What our residents say

IM Efficiency

Martijn Ildiz

May 2022

IM Efficiency is ready for 'next step' on the Automotive Campus

Making freight transport sustainable is quite a challenge. Alternatives to the traditional diesel truck do exist, but they are expensive and there are still many practical drawbacks. That does not mean that no steps can be taken with the current diesel fleet. Founder Martijn Ildiz of IM Efficiency is committed to reducing the consumption and associated emissions of trucks by making smart use of solar energy. "Our product SolarOnTop is mature and we are ready for the next step. We want to take that step from the Automotive Campus."

How did the idea of putting solar panels on truck roofs come about?

"Until a few years ago, I did a lot of 'freerunning'. In cities you run over obstacles such as cars, walls and roofs. I saw solar panels on many roofs and thought: why not put those panels on truck roofs to use the green energy of the sun while driving? A lot of attention is being paid to the greening and electrification of passenger cars, but it is precisely with trucks that you can achieve a significant reduction in CO2. After all, they drive long distances and trucks consume a lot of electricity in the process. This energy is generated by the dynamo. This is a very inefficient process. In short, there is a lot to gain here. In 2014, we started with the idea. Two years later, we had a concrete plan in place."

How exactly does it work?

"The solar panels actually turn the truck into a mild hybrid. While driving, this enables us to reduce consumption and achieve savings of around 6 percent. The flexible lightweight solar panels turn the trailer into a mobile solar farm. The sustainably generated electricity can also be used when the driver is stationary, for example for air conditioning, a TV or microwave. That is a lot more efficient and environmentally friendly than the usual way. The possibilities can of course be expanded. You could use the energy for cooling goods or for operating your tailgate."

For which target groups is this solution interesting?

"SolarOnTop is primarily intended for heavy goods transport and long-distance transport. Transporters who drive all over Europe and do a lot of mileage. We can work with all major brands and have contact with all major manufacturers. Think DAF, Scania, Mercedes. We explain what we are doing so that it does not affect the warranty for the customer. The solar panels can be mounted on almost all trailers. Only containers are not possible. These are stacked on top of each other on ships. The panels can't withstand that."

Why is the Automotive Campus an ideal place for you to be?

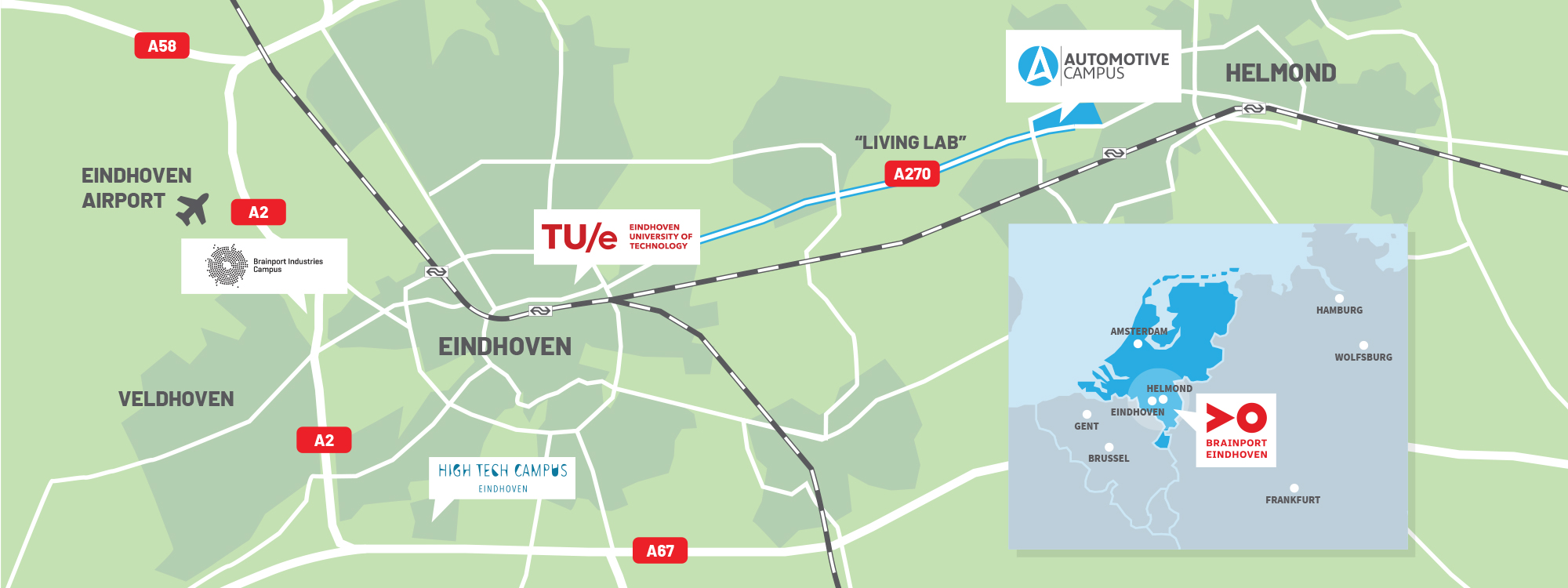

"The campus in Helmond came into the picture for us fairly quickly. We started in Heerlen, where I and my co-founders are from. We still have our production location there. The location on the Automotive Campus offered - and still offers - us opportunities to grow. It is an inspiring environment with many interesting companies and startups. Many parties are involved in beautiful technology, for example in the field of batteries and solar energy. Not only are there interesting residents walking around, but there are also many other guests, such as financiers, journalists and politicians. The campus has appeal and there are great opportunities."

What goals have you set for the coming period?

"We really want to get going now. We've recently gained a number of great investors. That offers great opportunities for us. Last year we grew from five to fifteen people. Our product is now really mature, all the teething problems have been solved and we can start producing in series. The idea is to take the 'next step' this year in Helmond. We are outgrowing our facilities in Heerlen. The Automotive Campus offers us opportunities to continue and to serve large parties. It would be great if we could help a number of larger transporters make their fleets more sustainable this year."

What are the biggest challenges here?

"The labor market is tight, but for the time being we are managing well to find new colleagues, partly through good contacts with universities. If we want to grow further, we will have to invest in this. A good team is a must for success. At the moment, chip shortages are particularly problematic. Although there are actually no chip shortages, but a shortage of many parts. That demands a lot from your purchasing. You have to anticipate the situation cleverly. But we'll get through it. We now want to go full steam ahead and make a difference!"

Automan

Michiel Pas

Maart 2022

We like to know if the candidate is a real 'Automan'

"Automan is a service provider, connecting automotive talent to automotive companies," is how Michiel Pas characterizes the company, which has been based at the Automotive Campus since 2005. "We are active in the labor market, but we focus more on professionals in Sales, Marketing and Management for car repair companies, dealers, service companies, leasing companies, mobility companies and various OEMs. They can be starters with at most one or two years of work experience, experienced sales and account managers, managers with technical talent as well as senior managers."

"We usually don't target individuals who are already actively looking for work," Pas clarifies. "Those often already have several options open. We prefer to look for a candidate in a targeted way, who meets the profile of the client, so that we can quietly form a picture of the candidate and of the fit with the new employer. We also do not hesitate to think out-of-the-box when looking for candidates and to look outside the automotive sector. This often results in surprising candidates with a fresh look at the job. But of course we are looking for real 'car men and women' with a passion for cars, trucks, buses, commercial vehicles and mobility."

Pas still sometimes suffers from the image that many outsiders have of the automotive sector. The work is often associated with cold and messy workshops and dirty hands. But the automotive industry has changed a great deal due to digitalization and the rise of electric vehicles, and that development continues. New mobility concepts have created many new roles and functions, which no longer come into contact with vehicles and technology at all."

Pas notes, that there have been major changes in the labor market in recent years. "Due to corona, employees have become more reluctant to change jobs, but this trend was actually visible before that," he says. "Young candidates in particular are more demanding and want more security before accepting another job. For them, it's not just about salary, but they also want to know, for example, who the colleagues and managers are, what the company culture and atmosphere are like, whether the job is challenging enough, what the new employer's financial position is like and what career opportunities are possible in the longer term. They want to know what they can learn and how they can develop themselves. They also want to talk about flexible working hours, parental leave, training and other 'soft' working conditions, because work-life balance is very important for the younger generation. These kind of topics are not always easy to discuss in the automotive sector, which is still fairly traditional. The younger companies on campus are responding much better to the wishes of the younger generation and are also looking internationally."

Pas notices that employees are again cautiously looking around for new opportunities now that the end of the corona crisis is in sight. "They are critically about their own position and many feel they have missed a step. For us, it is therefore important to keep good contact with candidates, but employers must make the retention of good staff a spearhead of HRM policy."

Automan has been located on the Automotive Campus since 2005. Although the company mainly does a lot of business off campus, Michiel Pas thinks the campus is a great place for his company. "The campus is a melting pot with different types of companies. Training courses, product launches and events are organized here, which creates a huge dynamic. And for us, of course, the students from the automotive courses are also interesting."

Jumbo Groenewegen BV

Ad van Nijnatten

December 2021

Students get a virtual tour of the factory in Bosnia

Jumbo Groenewegen, manufacturer of trailers and semi-trailers, has been based at the Automotive Campus in Helmond since the end of 2018. The facility employs about 12 employees, who are engaged in marketing and sales, engineering and work preparation, among other things. In addition, parts such as wheels, tires and other accessories are mounted on the trailers in the workshop. In addition, the trailers in the Netherlands are inspected by the RDW. The factory of Jumbo Groenewegen, where the trailers are produced, is in Bosnia. Almost 200 people work there. In addition to trailers, machines and other products are also manufactured there.

"We are an automotive company, but with us it is all very coarse," is how Ad van Nijnatten characterizes the company, where he is director business line trailers. "In the factory, profiles and sheet metal are cut with lasers, there are bending machines, welding, spraying and assembly."

For Jumbo Groenewegen, the cost price of trailers and semi-trailers is an important key figure; especially since competition is fierce. "That's why we are always looking at smart production methods and optimizing the work and work processes. We often work with students from Summa College or Fontys Automotive, for example, both of which are also located on the Campus. They have to learn to assess companies and processes. Our employees all become a bit company-blind after a while, but students look at the company with fresh eyes and they -mouthed as they are these days - sometimes push us quite a bit."

Sending a group of students to a factory abroad for a viewing is very expensive and time-consuming. Until recently, Fontys still worked with course books, in which the activities of a company were described (in text). On the basis of this, students had to analyze a company and come up with improvement proposals. Clearly, that kind of input is not ideal. "Recently a delegation from Fontys traveled to our factory in Bosnia. Interviews were done there and a lot of video and 3D material was recorded - even with the help of drones. That material will be offered digitally in an innovative way starting next semester. Students can watch it and analyze the business processes in our factory based on it. Specific assignments will also be offered. This way of working makes it much easier for them because now they literally get a "real life" view of the factory with lots of details. We are very curious about the improvement proposals from the first group of students who have worked with the material."

Ad van Nijnatten thinks the collaboration with Fontys is a great example of what the interaction between companies and educational institutions on the Campus can lead to. "You don't have this kind of beautiful cross-pollination on a normal business park."

Lex Boon, Director of Automotive Campus, also applauds such an initiative; "An inspiring example of co-creation on our campus. Students and organizations initiating such a virtual world together and actually shaping it, is for me the confirmation that a triple-helix ecosystem offers absolute added value, both for education and for organizations."

FEV Group

Edwin Kingma

November 2021

"We develop mainly behind closed doors"

The subsidiary FEV Netherlands BV of the German FEV Group settled into the main building of the Automotive Campus at the end of 2019 with around ten employees. It was the first location in the Netherlands of the BV founded in 2018, which until then had actually worked mainly at customer sites or from its headquarters in Aachen. "We like to be close to our customers in the Netherlands and Belgium, because our employees often work at the customer's location. Travel to and from Aachen and overnight stays proved very time-consuming and costly for both employees and customers," says Edwin Kingma, managing director of FEV Netherlands BV.

"The Automotive Campus is an excellent location for us and a perfect base for our activities in the Benelux, as we are close to a number of important automotive customers. Our accommodation on the Campus is flexible and scalable, and fortunately we don't have to worry about all kinds of facility issues ourselves. We want to eventually grow here to a team of around thirty to forty people, who can support our customers - of course in close cooperation and with the help of all the know-how at the headquarters in Aachen."

Kingma studied HTS Automotive Engineering and stuck around in the German automotive industry after his internship as a software developer. Among other things, he worked at the FEV Group. After returning to the Netherlands, he worked for another company for several years, but in 2017 he was approached by FEV Group to ask if he wanted to set up the Dutch branch. So Kingma knows FEV Group inside and out.

"FEV Group is an engineering service supplier, working mainly for OEMs and focusing on future mobility solutions," Kingma explains. "At its headquarters in Aachen, some 6,300 developers work on, for example, internal combustion engines, electric and hybrid drives and transmissions. However, this is almost always done under strict secrecy behind closed doors. Hence, our work is little known." Regularly, however, FEV Group presents concepts from new e-drive train components to complete shared cars as showcases of technological ingenuity and as a vision of the future of mobility.

Fier

Edwin Bestebreurtje

July 2021

Co-initiator AC FIER looks ahead

FIER as co-initiator AC FIER knows the history of the campus like no other. In fact, the expert in international automotive business development was one of the initiators of an Automotive Campus in Helmond. Edwin Bestebreurtje, Senior Advisor at FIER: "In those days, the region was mainly occupied with creating a home base for the automotive industry and thus joining forces. As FIER, we are still proud to have been able to contribute to this. Since that time, the campus has been growing continuously and there is no lack of national and international interest. That's great to see!"

Electric mobility One reason for the campus' continued growth is the rise of electric mobility. FIER initiates national and international projects to accelerate the transition to zero-emission mobility and renewable energy. Bestebreurtje: "You see continuous progress in the electric mobility sector. FIER focuses on sustainable mobility, particularly on new mobility, heavy duty trucks and charging infrastructure. I think that with FIER we have been involved in the birth of this trend with a role together with AutomotiveNL (now: RAI AINL) in the Interreg project ENEVATE and an important Trade Mission that we organized on behalf of the Ministry of EZK around the EVS in Shenzhen (China). During that trip, important Dutch parties, including startups at the time, sat down with Chinese parties to exchange knowledge and experiences. That visit to China led, among other things, to VDL running the first electric European city buses a few years later, which, incidentally, were tested at the Helmond campus."

Meeting on campus For internationally developing cooperation, physical visits are still of great importance. In particular, networking and meeting new people is often the basis for new initiatives and innovation. Networking has been somewhat difficult in recent months, but FIER looks to the future with confidence. Bestebreurtje: "Even during corona, the automotive and mobility sector has not been idle. I therefore expect a lot of news in the coming years." FIER hopes that after the summer the campus will soon organize events and physical meetings. Bestebreurtje: "That's really the added value of the campus: the doors are open so that we can move quickly and make steps together, both in the Netherlands and internationally. This is how startups, but also larger companies, grow and make great contributions to the future."

Voitures Extravert

Martijn van Dijk

May 2021

Voitures extravert is specialized in the complete conversion of classic fuel-engined cars into electric cars. Although CEO Martijn van Dijk and his partner Jurgen Moerman are crazy about French and German classics such as the 2CV and Mercedes, they decided to convert Porsche 911’s.

“The choice for the Porsche 911 is mainly based on its price value. We completely convert our cars. So when you drive our Porsche, it feels like you are driving a true classic, but under the hood you will find the latest technology. Also, the bodywork has been radically modified. This kind of investment would not be worth the effort with a 2CV or a Renault 4, because with these types of cars the total price after conversion is out of proportion compared to the actual value of the car. This is not the case with the Porsche 911.”

The choice of the right classic car therefore was essential for Voitures extravert. "The Porsche 911 is a true classic, with an iconic design, which attracts a lot of interest. But you have to be able to locate your customers. So before we started, we did an extensive market research. Based on these findings we decided not to exhibit our cars at the

renowned car fairs. For us, lifestyle events such as the European Fine Art Fair are much more interesting. We sell our cars in the United States, Switzerland and the UK, among others. ”

Voitures extravert has a production capacity in the range of 6 to 36 cars per year. For the work on the car and the required parts the company depends on its own network of suppliers. “We do not produce industrial volumes,” Martijn explains. “Our partners know that we only need supplies in small numbers. The cars are assembled at the Automotive Campus in Helmond, and the software and all electronics are installed at that same location. The presence of specialized automotive companies in the Eindhoven region is an important advantage of the Campus. In total, I think we outsource about thirty percent of the development, the conversion work and the components in the region.”

Lightyear

Maijke Recerveur

April 2021

Some weeks ago Lightyear announced that the company had succeeded in raising 48 million dollar for financing further expansion as a result of a very successful funding round. This should - among others - lead to the presentation of the first production car for consumers at the end of the year. Maijke Receveur, Chief People & Processes Officer at Lightyear, about the role of the Campus:

“Our presence at the Campus in Helmond since 2016 has for sure contributed to the growth of Lightyear. The campus has helped us to scale-up in a flexible way. We started off with less than 15 employees, but in the meantime we have become more than ten times that big. Thanks to the fast response of several organizations such as the Campus, the municipality of Helmond and Van de Ven Construction Company the availability of accommodation and working space have never limited our growth. Moreover, the Campus has actively contributed to our growth by opening its ecosystem to us. Because we were involved in events organized by the Campus and in visits by governmental organizations, students and companies, we have been able to present our company very well and to extend our own network as well.“

“We expect to employ 300 people at the end of the year. Therefor we are developing a short and long term vision for Lightyears accommodation. On the one hand we need accommodation for specific activities, but on the other hand we expect that a part of our employees will be working from home in the future as well. We think, that the Campus will be able to facilitate further growth of our company.”

Vialis

Robbert Wittmaekers

March 2021

Robbert Wittmaekers, General Manager of Vialis at Koninklijke VolkerWessels: “What was considered normal in traffic management has been turned completely upside down this year. “Because we don’t know for sure if things will return to normal, certain questions arise. For example: do we need to broaden roads?”

“Of course Corona has changed our perspective, but some transitions already began in the years before this crisis. Compared to the past, we are less willing to be in traffic jams and we see a clear shift from priorities to sustainability. This is an opportunity for the automotive industry. For example, our systems no longer direct traffic solely based on the amount of traffic, but also based on sound, light and environmental values. Concrete is important, but it no longer stands alone. The combination with systems is now most important. ”

Stay Tuned

Our

partners